Flat-top Hammerhead

WOLFF 6031.12 Clear US

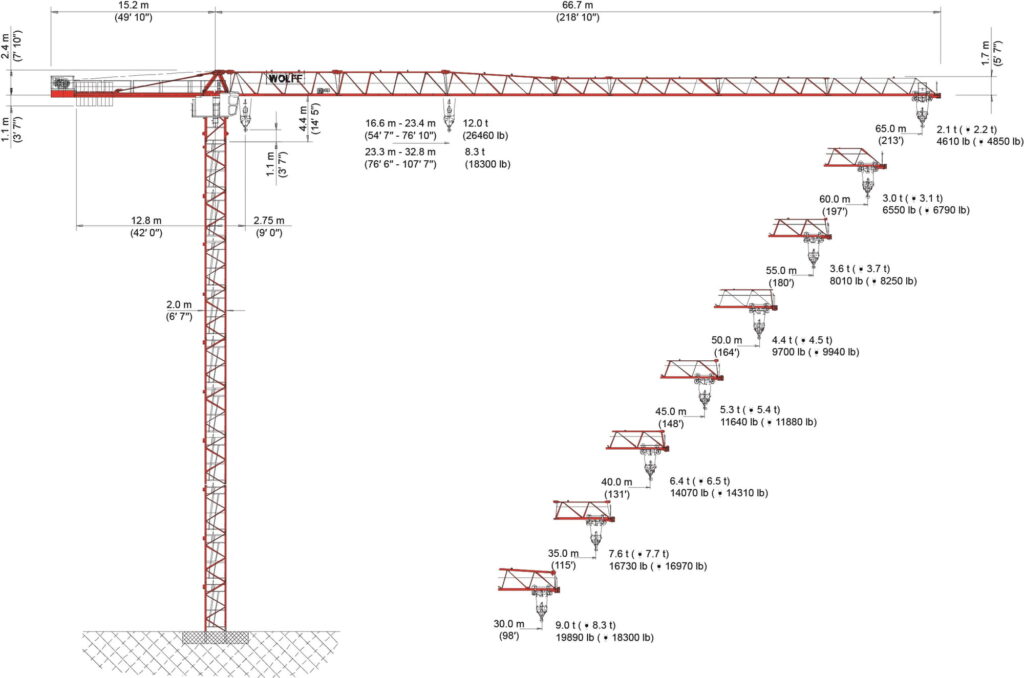

Technical information

| Norms | EN 14439 |

| Max. load capacity | 12.0 t (26460 lb) |

| Max. jib radius | 65.0 m (213′) |

| Rope falls | 2 | 4 |

Power requirements

| Hoisting gear: | ||

|---|---|---|

| Type | 845 FU | |

| Power | kW | 45 |

| Current | A | 88 |

| Crane: | ||

| Operating current | A | 81 |

| Peak current | A | 123 |

| Supply line: | ||

| Cross Section A | mm² | 35 | 50 |

| Max. fuse | A | 110 |

| Max. length S2 + S3 | m | 203 | 290 |

| Connected power | kVA | 68 |

| min. required generator power | kVA | 136 |

Description

30 m (98′) basic jib with trolley gear. Extensions up to 65 m (213′) radius in 2.5 m (8′) steps. Slewing frame with driver’s cabin, control cabinet, two slewing gears, ball race bearing with

central lubrication unit and slipring system. Counterjib with hoisting platform and counterweights.

Drive Technique

All drives frequency controlled squirrel cage motors, fully thermal protected. Hoisting winches Hw 845 FU or Hw 875 FU. Automatic re-reeving device (from 2-fall to 4-fall operation). Two slewing gears with electrically operated weathervaning device. Automatic windforce compensation controls. Trolley gear.

Electrical Equipment

Multivoltage equipment for supplies of 480 V Y / 277 V 60 Hz. Electronic safety crane controls with bus technology. Incremental absolute encoders for all operating movements. Electronic load measuring device at basic jib section. Multilingual graphic display showing information to operator, both operational and diagnostics.

Safety Devices

Electronic overload protection system. Increased load moment limitation by automatically

hoisting speed reduction. Menu guided setting of overload protection system and of all limiters from operators cabin. Working space limiter. Anti collision interface. Trolley rope breakage safety device.

Tower Elements, Climbing Device

Tower configuration of WOLFF system tower elements. WOLFF slug bolt connection. Detachable hydraulic WOLFF system climbing device KWH 20.3 or KWH 20.6. WOLFF system inner climbing device KSH 20 SH.

Cross Frame KR, Mobile Cross Frame KRF

WOLFF cross frames KR can be used with gauge from 6.0 m up to 10.0 m (20′ – 33′). WOLFF cross frames can be modified to KRF.

Power Requirements and hook paths (Slewing part)

67 kVA (Hw 845 FU), hook path 190 m (623′) in 2-fall operation.