for Heavy Construction Projects

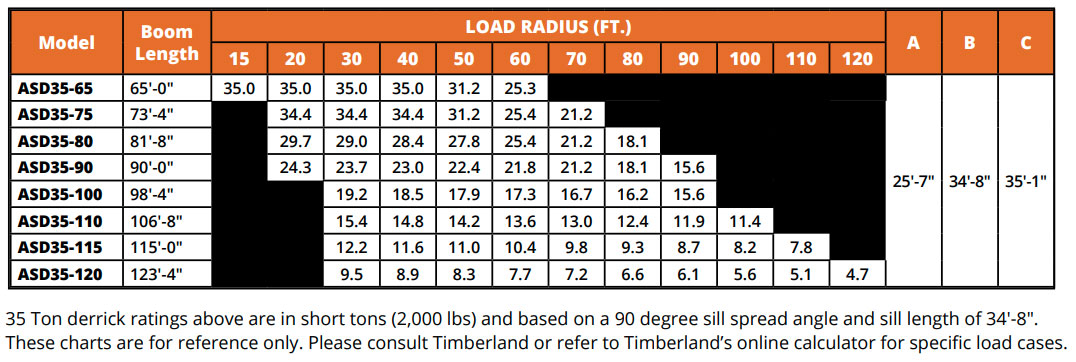

Timberland 35 Ton Derrick

Description

Engineering and Design

Timberland designs and builds a broad product range of derricks including modular portable derricks which can be transported up and down high-rise buildings via elevator to high-capacity derricks installed on large civil and mining construction sites.

Features

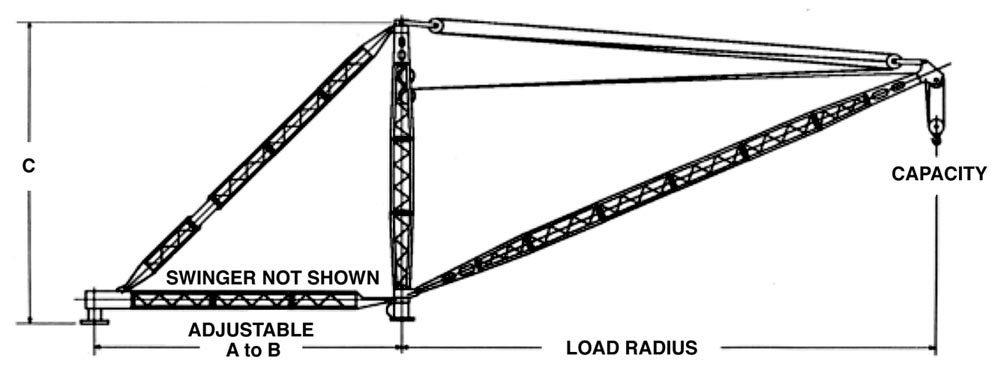

- Adjustable sill and leg lengths

- Adjustable sill spread angle from 45° to 100°

- Standard maximum boom length of 123′-4″

- Boom, mast, sill and leg sections 8′-4″

- Lattice construction

- Sheaves have machined rope grooves and sealed anti-friction bearings

- Mechanical boom angle indicator

- Electro-hydraulic swinger drive

- Swing limit switches

- Load & boom blocks

- Multi position mast base design

- Standard hoist package allows for max lift height of 850′ fully reeved

- 8 Part line for the load line

- 10 Part line for the boom line

- Rated minimum operating temperature -20°C (-4°F)

Options

- Bolt on rigging package

- Erection Gin Pole or Crane

- Load Moment Indicator (LMI) package including:

- Anti 2-Block

- Anemometer

- Load Sensing

- Digital display of boom and swing angles

- Beacon on top of mast

- Swinger remote control (25 ft. pendant)

- Additional 25 ft. remote extensions upon request

- Cold temperature package to allow for operation down to -40°C (-40°F)

- 1800’ 35 Ton Extended Lift Height Derrick option

Adjustability and Configurations

All of our standard stiffleg (fixed and adjustable) derricks can be configured into a Guyline, Column and Chicago Boom configuration.

Consult Timberland’s expert team for load capacity charts and any additional features required for your specific configuration and requirements.

Customization

Timberland thrives when custom applications are required. Consult our team of highly qualified engineers and senior sales consultants for custom derrick and hoist applications.

Modular Construction & Standardization

Timberland’s standard modular design allows for interchangeability between boom and mast sections as well as between leg and sill sections.

Our modular component design provides balance between practical set-up of the machine and ease of handling and transport.

Continued Support

Our team works hand in hand with customers and local regulatory authorities to ensure seamless project implementation.